In case you didn’t know, 1 horsepower equals the amount of power needed for one horse to lift 33,000 lbs. one foot in one minute, or 550 ft.-lbs. per second, known as torque. Once a system of measurement was in place for horsepower and torque all those years ago, we needed a device to measure it – enter dynamometers. Related Articles - How To Properly Read Your Spark Plug - Shop Solutions September 2023 - How to Properly Crate a Performance Engine for Shipping

When it comes to the many different tools an engine builder can have in the shop, there are very few as enticing as a dynamometer. If you’re looking to fine tune your engines and vehicles and prove they meet your horsepower goals, then a dynamometer is on your list of wants. Of course, you can always pay to use somebody else’s dyno set up, but why let the other guy have all the fun? Vehicle Test

Dynamometers are available in two main variations – the power absorption dynamometer and the power transmission dynamometer – respectively known as the engine dynamometer and chassis dynamometer. Within those two dyno varieties, the auto industry typically relies on inertia dynos, brake dynos and eddy current dynos.

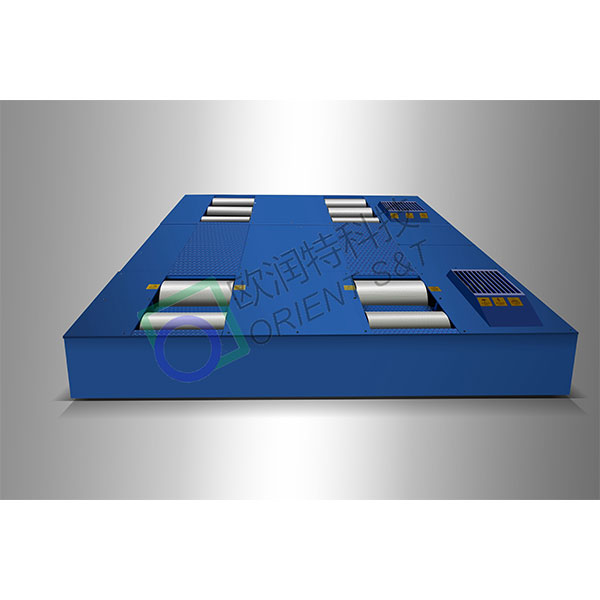

As you likely well know, engine dynos measure power directly at the engine’s crankshaft or flywheel by absorbing the force and calculating horsepower. The chassis dyno, on the other hand, transmits the load to simulate operation of a vehicle in a controlled environment. It measures acceleration and horsepower and calculates torque. Chassis dynos can measure that load from the vehicle’s wheel/tire in a wheel chassis dyno set up, or straight from the hub, otherwise known as a hub dyno.

Obviously, there are a ton of different reasons engine builders would want a hub, chassis or engine dyno, so we looked into why you might opt for a particular dyno over another, or why you may want multiple dynos for the ultimate set up.

When it comes to your traditional wheel chassis dyno, most folks explore the options of an inertia set up or an eddy current brake set up. Wheel chassis dynos have been the more popular option for engine builders because they’re easy to use and the price range is anywhere from $25,000 to $120,000, give or take. A majority of that price range is significantly less than hub dyno and engine dyno options.

“For quick and easy pulls, it is very easy to have a Dynojet on the ground that you can pull a car up on, strap the car down quick and go,” says Chris Wright, owner of Pro Car Associates in Akron, OH. “Inertia dynos are great for doing sweep tests. However, once you get into steady state tuning for drivability and things of that nature, then you need some kind of way to control that load, so you need an eddy current-type brake on there. That will apply a load to the roller/drum and hold the engine at a given rpm.”

Pro Car Associates has an eddy current chassis dyno that is rated to 2,500 horsepower.

“The problem you have with an eddy current chassis dyno like mine, for example, is it’s two small rollers,” Wright says. “It’s very easy to pull cars on, get set up and go, but when you get to really high horsepower stuff, like 900-1,000 wheel horsepower and up, now you’re dealing with tire to roller issues.”

One thing that has to be made clear when it comes to all chassis dynos is there’s no such thing as 100-percent accurate testing.

“If you were to take the same vehicle you tested on a wheel chassis dyno and put it on a hub chassis dyno, it will make more horsepower on the hub because you’re losing horsepower through the tire on the wheel chassis dyno,” says Steve Morris of Steve Morris Engines in Muskegon, MI. “That’s not due to slippage, but rather the tire itself, the air pressure in the tire, and the weight of the tire. With a hub dyno, there’s no wheel there. It eliminates that inertia weight from the wheel.”

In addition, the straps used on a wheel chassis dyno also put a load on the vehicle, which isn’t the case with a hub dyno.

“The way you strap the vehicle down changes the horsepower output reading because it’s all related to inertial and frictional losses,” Morris says. “A hub dyno’s horsepower number will always be bigger than a wheel chassis dyno.”

Those differences in accuracy have been made much better with today’s modern software, but no matter how good the software is, you will see differences in horsepower readings. As long as you understand that, it’s minor in the grand scheme of things.

That said, the way in which and how tight you strap down your vehicle on the wheel chassis dyno is crucial to ensuring it doesn’t move forward, backward or side to side.

“There are some safety issues you’ll have to take into account with a chassis dyno,” Morris admits. “Things can always go wrong. I’ve seen driveshafts fall out, and I had a diesel truck on my wheel chassis dyno that had a tire explode while testing. It shredded the side of the truck and threw chunks of rubber clear across my shop. Don’t stand next to the chassis dyno!”

Heeding Steve’s advice is recommended. Some danger is always present when dealing with high horsepower engines, no matter what your dyno set up is. However, with a chassis dyno, you’re getting a really simple and good method of tuning, and it also allows you to find any issues or problems in the vehicle before race day.

“I always use an engine dyno first,” Morris says. “The only reason I got a chassis dyno was because I got tired of customers who would be there with me during an engine dyno session and see that the engine was running and everything was good, but then they would put it in the vehicle and something would be wrong. Immediately, the customer thinks it’s the engine – it’s always something else going on from the flywheel back. I got the chassis dyno solely because there is always a wiring problem, or a mechanical problem, converter issues, etc.”

If you need a simple, easy and more cost-effective dyno solution, a wheel chassis dyno might be the answer you’re looking for.

In addition to the inertia chassis dyno and the eddy current brake chassis dyno, many engine builders with high-horsepower goals have been enamored by the hub eddy current dyno. As both Morris and Wright point out, the hub dyno is also easy to use, safer than its ‘tire on’ sibling, and more accurate.

“The hub dyno is a little bit more efficient and more accurate because you’re eliminating the tire,” Wright says. “Anytime you’ve got the tire to roller, you’ve got those frictional losses, and the way you strap the vehicle down, you have losses.”

As the competition for more horsepower and faster track times continues to increase, the most accurate numbers matter to engine builders and customers. That’s why the hub dyno has taken off. It can also handle more horsepower than traditional chassis dynos and engine dynos.

“A hub dyno can handle up to 6,000 axle horsepower,” Wright says. “The hub dyno is also superior from a safety standpoint. A lot of the hub dynos are on pods that you can lock in, or they have it on a rail that slides in so they don’t come off. Because this style of dyno locks in your hub, your vehicle is locked down. The only thing you may need to do for the really high horsepower stuff is just tie the front end down so it doesn’t lift.”

While the hub dyno is viewed as an option for the high horsepower folks, there’s no reason you can’t use it for smaller horsepower vehicles too.

“Ben Strader of EFI University has a hub dyno and he says he’ll put anything over 300 horsepower on it because it’s so easy to use,” Wright says. “You just hook the hubs up to it and you’re done. I’ve got my eye on an all-wheel-drive hub dyno. The rears are rated at 6,000 hp and the fronts are rated at 1,600 hp. The nice thing is you can test all-wheel-drive cars, but you can also just use the fronts to do some basic stuff or just the rears for high horsepower.”

Depending on the power level, hub dynos can come with movable pods, and some of the wheel chassis dynos are portable as well. However, once you get into the high-horsepower realm, you end up needing a designated area for these tools.

Another nice aspect hub dynos offer is in the software itself. Certain hub dynos can simulate actual drag strip runs with gear shifts and everything. What this option really comes down to is price and application, as most of these kinds of tools do.

“If you’re drag racing or building Pro Mod cars or really killer street cars, you’ll likely want the hub dyno,” Wright says. “Just keep in mind it’s more money. A hub dyno can run you $60,000-$80,000 and an all-wheel-drive system can go for around $120,000 or more. That’s why some shops might opt to keep a chassis dyno because you can buy one for $25,000-$35,000 and you’re up and running with a two-wheel-drive dyno that you can tune with and do everything you need to do comfortably up to 800 wheel horsepower or so.” Engine Dynos

The one dyno any serious engine builder can’t argue against needing or wanting, is an engine dyno. The big difference with this dyno versus the chassis set up is obviously no vehicle involved – it’s just the engine. While the engine dyno may sound like the most simple of the three dynos on paper, it’s actually the most involved, by a long shot.

“Engine dynos can cost anywhere from $60,000 to $4 million,” Wright says. “People don’t realize it’s not just about buying the engine dyno unit itself. It’s about everything in the facility that goes around it.”

The dyno room, which houses your engine dyno unit, air, exhaust, water and fuel supply, is a whole other additional cost to setting up a proper engine dyno. It’s also something to consider when thinking about the space it will require in your shop. There are varying degrees in which you can set up this space, and more info can be found on page 8 for best practices.

“You don’t have to do an explosion-proof room,” Wright says. “A lot of people will just build a drywall room, but those people have never seen an engine come apart and a flywheel go around the room like a buzz saw cutting everything into pieces. That’s why you build a dyno room. Ours uses 12˝-thick blocks that are sand-filled and it has a concrete ceiling.”

When it comes to the engine dyno unit itself, there are a bunch of options available to engine builders. Again, your choice will boil down to cost and application.

“The water brake dyno has become the main engine dyno system because it’s simple, easy and more cost-effective,” he says. “To do an eddy current style dyno comparable to what our water brake dyno can do, the dyno unit itself was $1.5 million. You don’t have to take it to the extremes by any means. You could do it within a budget and spend $150,000-$200,000 and have yourself a nice engine dyno with a basic room and do what you need to do.”

No matter the style or the ultimate cost, serious engine builders will eventually want an engine dyno as part of their shop. The tool helps with engine development, tuning and can be a money maker with customers and other shops looking to use it.

“If you’re doing true engine development, you need an engine dyno,” Wright says. “If you’re looking to make changes to your engine set up, it’s a hell of a lot of easier on an engine dyno and a lot safer. Now, if you have the capabilities to have both an engine dyno and chassis dyno set up, that’s the ultimate. Many big race shops have both, or a hub dyno.”

If you’re lusting after a dyno, whether it’s a chassis, hub or engine dyno, you have a lofty expense to think about, but one that can take your engine building to the next level. Of course, with all the options available, it’s nearly impossible for us to break them all down for you, given there’s so many variables at play.

Just keep in mind what kinds of engine applications you’re typically dealing with and where the majority of your horsepower range is within. Do you go beyond just engine work and do installations in vehicles or want to do tuning in the car? Or are you looking to build the highest horsepower engines and fastest vehicles possible?

Answering those questions will at least set you in the direction of which dynamometer is going to benefit you the most. From there, it comes down to budget and shop space. Dyno manufacturers such as Dynojet, Mustang, Taylor, Super Flow, Land & Sea, Dynocom, Mainline, and many more, will be happy to help you with your dyno needs. EB

Following Chevy’s introduction of its popular small block V8 in 1955, the OEM needed something larger to power its medium-duty trucks and the heavier cars that were on the drawing board at the time. Enter the big block!

Chevrolet’s big block engine doesn’t need an introduction, especially for this crowd. It’s a certified staple of street cars, trucks, race cars, and all sorts of performance vehicles. But, we wouldn’t be doing our due diligence if we didn’t provide a proper overview. Chevy’s big block engine is a series of large-displacement, naturally aspirated, 90-degree, overhead valve, gas-powered, V8 engines that were developed and produced starting in the late-1950s.

Engine and machine shop tips and tricks.

Engine and machine shop tips and tricks.

For more than 90 years, Pennzoil has worked alongside the American Petroleum Institute (API) to ensure Pennzoil products meet – and often exceed – the stringent requirements of motor oil specifications implemented to best help protect the performance of your engine. Related Articles – Nitrous Update – Heavy-Duty Diesel Engines, Equipment and Replacement Parts – Diesel Piston

The use of nitrous oxide in diesel engines is not a new concept. In fact, it has been used in drag racing for decades. However, it is only in recent years that it has gained widespread popularity in the worlds of diesel truck pulling and drag racing. Now, it seems as if almost everyone in the competitive scene is using it.

Pro Motor Engines in Mooresville, NC and owner Dennis Borem have a rich history in NASCAR and other forms of racing. We got to visit the shop earlier this summer, and the team was wrapping up a dyno session on a newly assembled LS3 engine for TA2 racing. We got the full details of the

During our week in Mooresville, NC, we couldn’t leave town before visiting Pete Harrell and his shop, Harrell Engine & Dyno. We stopped by to see what engines Pete was building, what cars he was tuning and what other cool things he was working on. He was kind enough to give us the full tour.

With the SML engine fully assembled, Jason Sack visits Steve Morris Engines to help with the dyno testing and tuning, as well as fitting the new SML into the Cowboy Up Nova. Related Articles – Gibbons Motorsports’ 598 cid Big Block Chevy Engine – Assembly of a Steve Morris Engines SML for Jason Sack –

The EMU Pro is an advanced system that is easy to install and operate, and provides complete control over all aspects of the engine’s operation.

Mot List Of Acceptable Equipment Content for engine professionals and enthusiasts